Introduction

30% Brighter LCD Screen

Compared to previous model (DG-3), DG-3x has TFT liquid crystal whose brightness has increased by 30%. The view angle has expanded and the visibility rate has improved.

You can improve accuracy of analysis by using high resolution image taken with 2.3 MP CCD which can meet a wide variety of needs from observation at the site to research and development.

Scales, grids and magnification indicators on a screen

Scale and magnification are shown at lower right of the monitor. You can clarify magnification of the object at the time of shooting by making it a yardstick of the size of the object at the time of viewing or by recording the object while indicating scale magnification ratio.

By using the 7 additional scales (with Grid Editor software), you can confirm quality acceptance/rejection criteria and size of the problematical part which are difficult in judgment at the site, the finish of the product and so on.

Versatile function

- Light and easy to carry

With its compact design, it is as light as 490g. (When battery and CF card installed) Power source is a lithium-ion battery or an AC adaptor. You can shoot a magnified picture everywhere you want.

- Touch and View

Just touch the lens to the object and you can take a picture easily. You can observe an object as it is even if the object is difficult to carry or even if it cannot be disassembled, cut or processed.

- Data can be put into a CF card.

Recorded JPG data can be connected with outside devices including your PC printer thanks to the CF card.

- Output to an outside monitor

Many people can view the image together with TV monitor. You can record moving pictures if you connect DG-3x to a DVD recorder.

- Easy to focus

You can confirm focus if you zoom the image on the monitor temporarily before you pop the shutter. A focus indicator shows how the adjustment condition of the focus is. Anyone can shoot a vivid image easily.

- Options

-

You can construct the most suitable observation system to achieve the purposes by using various lenses of different magnification and lighting methods. Compatible with a C-mounted lens, an endoscope and a microscope too.

You can construct the most suitable observation system to achieve the purposes by using various lenses of different magnification and lighting methods. Compatible with a C-mounted lens, an endoscope and a microscope too.

Lenses

- Standard Lens(30x /50x /100x /200x lens)

- High Resolution Lens(100x /200x /500x /1000x lens)

- Micro/Macro Lens(0x ¡Á 30x Lens)

- Bore Lens(with a side-mirror tube)

- Zoom Lens (25x ¡Á 200x)

- Coaxial illumination unit

Lenses of other companies can be used via C-mount adapter.

- Attachment for microscope

- Industrial fiberscope

- Industrial borescope

Stand

Content of Basic Set

Cordless Microscope DG-3x

- Users' guide for Grid Editor Software

- Grid Editor Software(CD-ROM)

- CF memory card(256MB)

- C mount adapter and C mount cap

- Video output cable

- Rechargeable lithium-ion battery

- Battery charger & AC cord

- AC adapter

- Neck strap

- Users¡Ç guide

- Carrying case

Specifications

| Image capture element | 1/1.75 inch interlace scanning CCD (Aspect ratio 3:2¡¡RGB original color filter square pixel) |

|---|---|

| Pixels | Total pixels approx. 2.3 MP(1901 (h)¡ß1212(v)) Effective pixels approx. 2.16MP(1816 (h)¡ß1208(v)) |

| Mount | Scalar DG mount (C-mount compatible with C-mount adapter attached) |

| Shutter speed | 1/45-4 sec |

| Storage | CF memory card ¡üNORM mode¡§1792x1184 pixels, approx. 500KB ¡üFINE mode¡§1792x1184 pixels, approx. 900KB ¡üZOOM mode¡§ 896x 592 pixels, approx. 500KB |

| CF memory card number of recordable images | ¡üNORM mode¡§approx. 638 images with 256MB ¡üFINE mode¡§approx. 283 images with 256MB ¡üZOOM mode¡§approx. 638 images with 256MB ¢¨Number of images will depend on type of images captured. |

| Monitor | 3.5-inch 230,000 pixel TFT LCD(960x240 dots) |

| Video output | NTSC |

| VIDEO OUT terminal | 3.5mm monaural mini-jack(LCD monitor side) |

| REMOTE terminal | 2.5mm stereo mini-jack(doubles as external flash cynch) |

| DC IN terminal | EIAJ standard type-2 DC jack(center plus) |

| Light switch | Light A, light B interchangeable for lenses with built-in light sources) |

| Output | voltage 5V, maximum output current 250mA |

| Input | voltage DC6.0V¡Þ5% 1A; battery operation:6.0V-7.2V¡Þ5% |

| Power consumption | approx. 6w (microscope only) |

| External dimensions | 98¡ß201.5¡ß68mm |

| Battery running time | Consecutive monitor use: 1 to 1.5 hrs (depends on use settings) Consecutive recording: 1hr(depends on use settings) |

| LED for power check | Power on¡Ägreen LED on Low battery ¡Äred LED on Power off¡Ä both LEDs off |

| Weight | approx.370g(microscope only)approx. 490g(with battery and CF card) |

| Installation screw | Camera screw |

| Operating environment | 0 to 40¡î |

| Storage environment | -10-55¡î |

| Operating and storage humidity | 30-85%(no condensation) |

Applications

- Usable Scenes

- If you need to

- observe the object in the production line.

- observe the object which you cannot move.

- observe the tip of the edge of a machine that you cannot remove.

- use it outside the building without any power source.

- use it while you are on a business trip.

Examples of application

- Car-related and machine-related objects

-

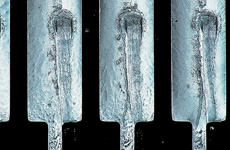

- Nest, crack of forged products for cars

- Surface finish condition of dies, surface condition of machined parts

- Crack and pinhole of various parts

- General defects of forged products

- Foreign material identification of car body painting surface

- Scratch, crack, dent, etc. of each part of cars

- Surface finish condition of die machining

- Crack, scratch, dent, etc. of car body painting surface

- Scratch, burr, etc. of cylinder head during processing

- For evaluation of fatigue test of metal materials of car parts

- Scratch and inner observation of the inside of car engine parts

- Confirmation of crack within resin molded parts

- Confirmation of crack/pinhole of parts

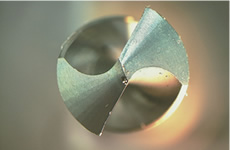

- Observation of wear and tear of cutting tools and grinding tools

- Observation of welded condition

- Surface observation of metal processing

- Medicine manufacturing-related and bio-related objects

-

- Identification, etc of tablet surface scratch, granular forming condition of granular agents, foreign materials and so on

- Cosmetic development-related and skin observation, etc.

- Inner surface treatment condition within a cultural tank

- Analysis of foreign materials

- Surface observation of a gelatin capsule (confirmation of liquid leak)

- For maintenance of machines

- Analysis of foreign materials

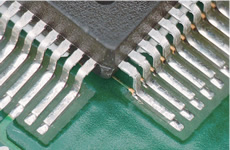

- LCD-related and electronic parts-related objects

-

- Confirmation of crack of LCD module and disconnection of flexible PCB

- Check of disconnection of LCD module PCB

- Observation of dirt and dust of £ÐCB(measures for claims)

- Glass PCB of Plasma TV

- Analysis of defects in soldering of IC lead

- Plate making and printing-related objects

-

- Condition of scratch on film making roller surface, for maintenance purpose

- Observation of functional film surface, observation of scratch

- Observation of appearance of Tetoron film

- Observation of ink attachment in printing materials

- Confirmation of defective crimping of films

- Others

-

- Maintenance of pipes at a plant

- Observation, etc. of equipment deterioration within an electric power plant

Gallery

Using Side Light Zoom Lens

Side Illumination(Light from circumferential direction)

¡ÚClick to Enlarge¡Û Magnification is indicated in the lower right of each pictures

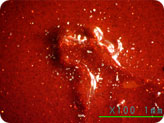

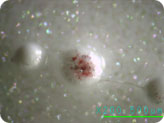

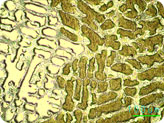

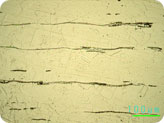

Coating Surface

Scratch on coating surface

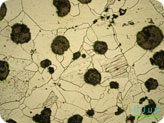

Foreign substance on coating surface

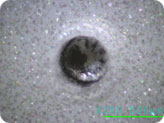

Apparatus

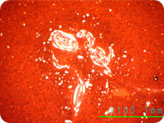

Engraved mark

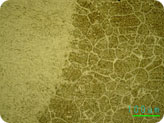

Uneveness from a press

One-Sided Illumination(Light from one direction)

¡ÚClick to Enlarge¡Û Magnification is indicated in the lower right of each pictures

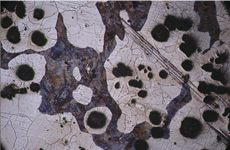

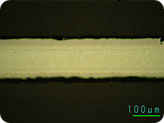

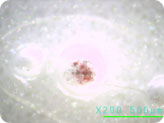

¡ÚClick to Enlarge¡Û Examining a nickel-based superalloy with a grating in the center using Coaxial Illumination Lens Holder Unit at 100x